Service Hub: Transforming Fragmented Workshop Processes into a Connected Service Ecosystem

Automotive service centres commonly rely on paper, sticky notes, and spreadsheets to plan daily workloads - a patchwork system creating rigidity and chaos.

Technicians lose time chasing updates, managers struggle to optimise capacity, and customers end up suffering from a lack of certainty and visibility.

I led the research and early design for a new digital scheduling experience within ServiceHub, helping workshops plan, assign, and track jobs automatically, freeing technicians to focus on what matters most: the work itself.

Product

B2B Saas Workshop Management Platform

Skills

Research, Prototyping, User Testing

Role

Research lead & Designer

Timeline

6 Months

Challenge

No two workshops ran their day the same way. Some used magnetic whiteboards, others printed schedules each morning and would find themselves rewriting them by midday. Every change triggered a scramble to reshuffle jobs manually.

This inconsistency caused missed deadlines, overbooked technicians, and poor communication with customers.

Our task was to design a system that simplified scheduling, improved visibility, and reduced administrative burden, all without losing the flexibility technicians depended on.

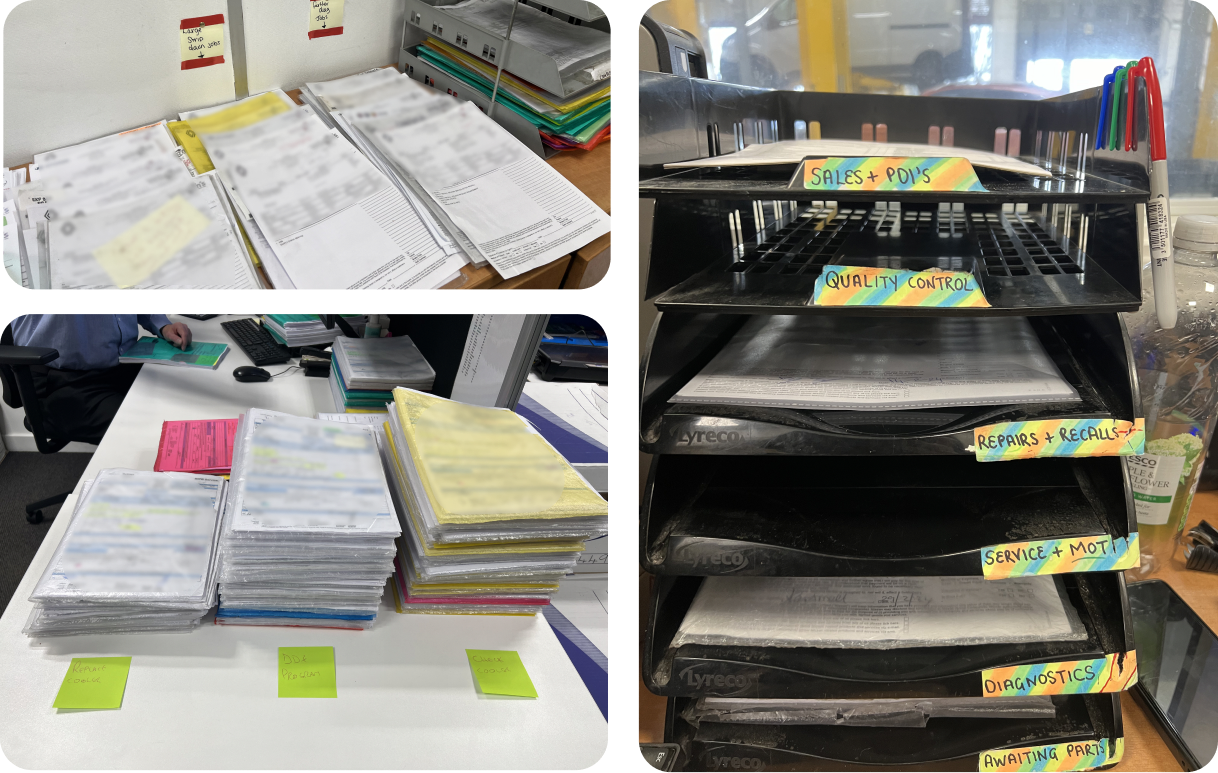

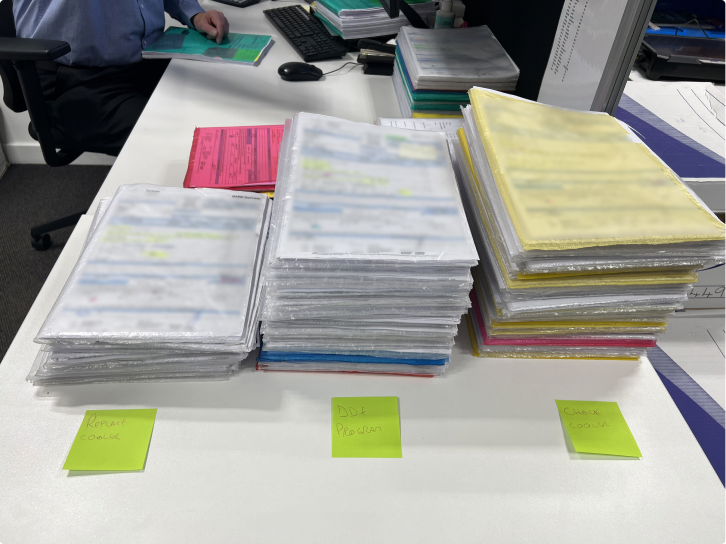

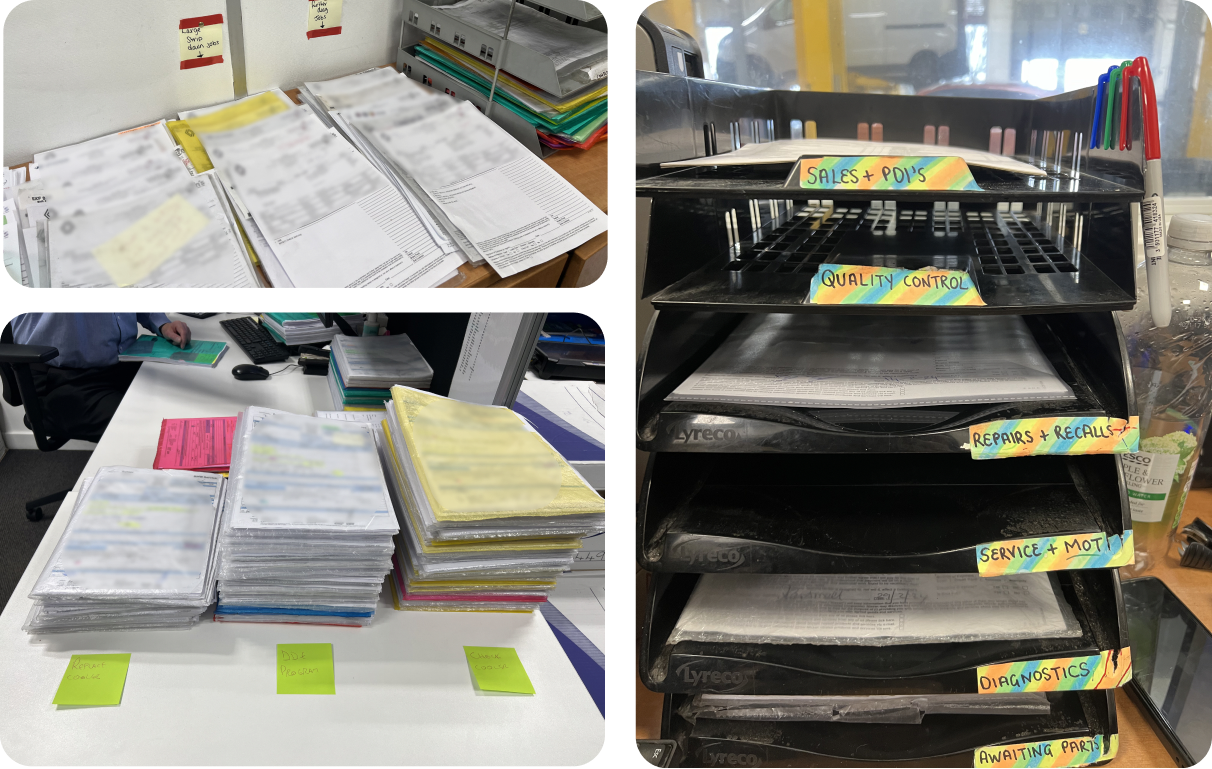

Paperwork Overwhelm

Job prioritisation and allocation depends on vast piles of paperwork across the workshop. Job cards are frequently lost, and jobs are not allocated in an optimal order.

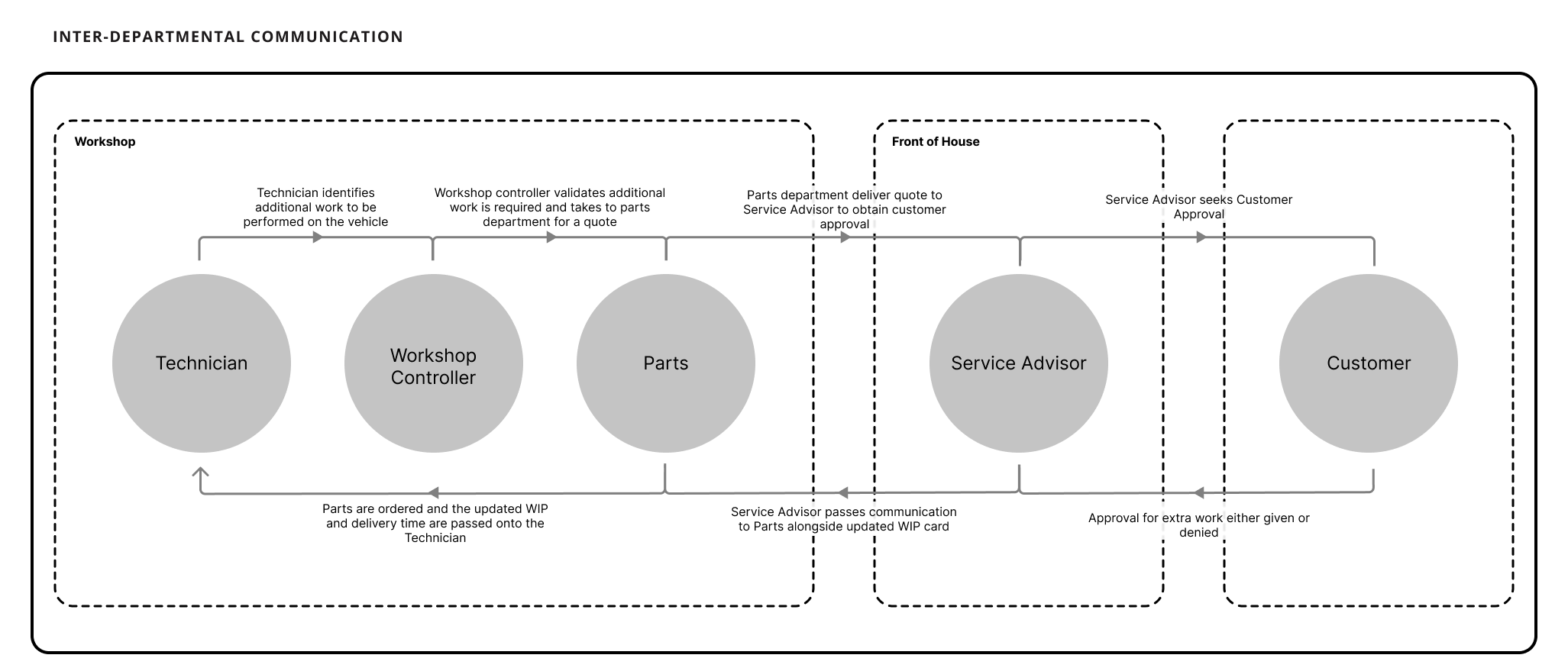

Communication Challenges

Front of house teams chase down individual technicians to get updates on the progress of jobs, often while the customer waits on the phone for an update.

Customer Experience Suffers

These factors stack up, fragmenting the customer experience. For example miscommunication that their vehicle is ready, only to arrive and it’s still being worked on.

Approach

Research

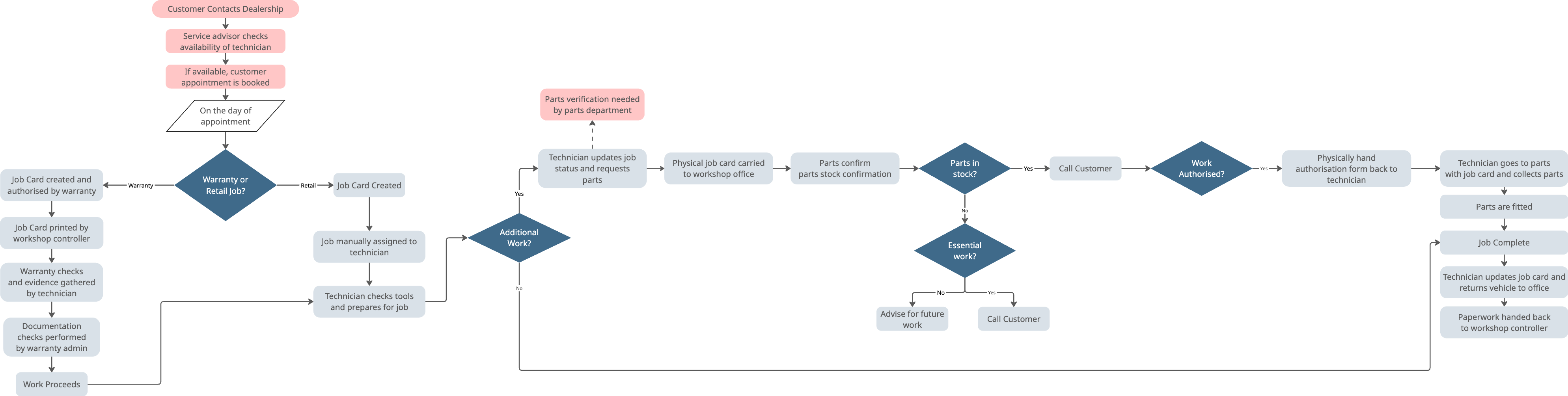

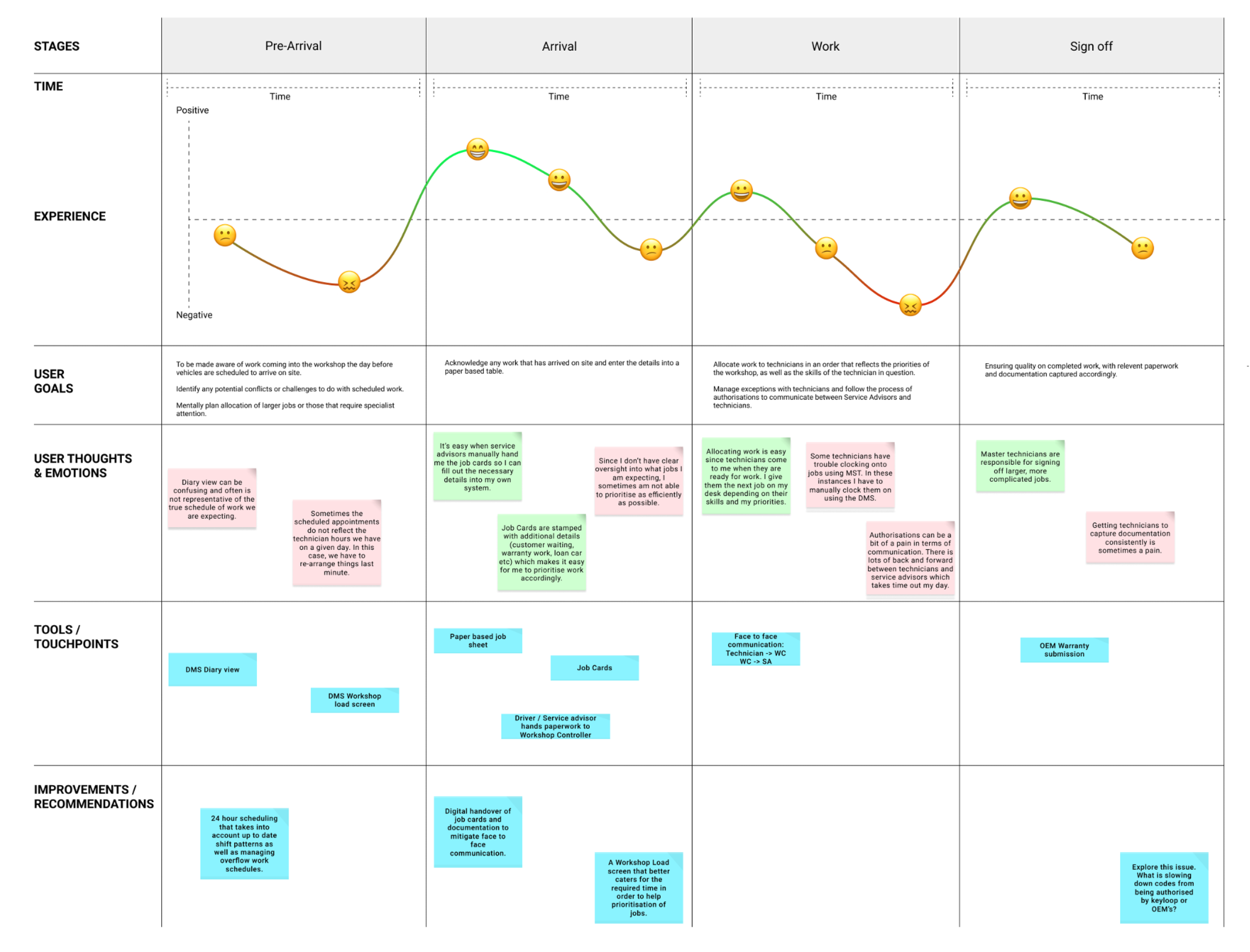

To capture qualitative data that would help prove or disprove our early assumptions, I partnered with 6 of our key clients to undertake a series of site visits. The visits were an opportunity to shadow workshop staff to understand their workflows, and identify pain points which would later represent opportunity for a solution.

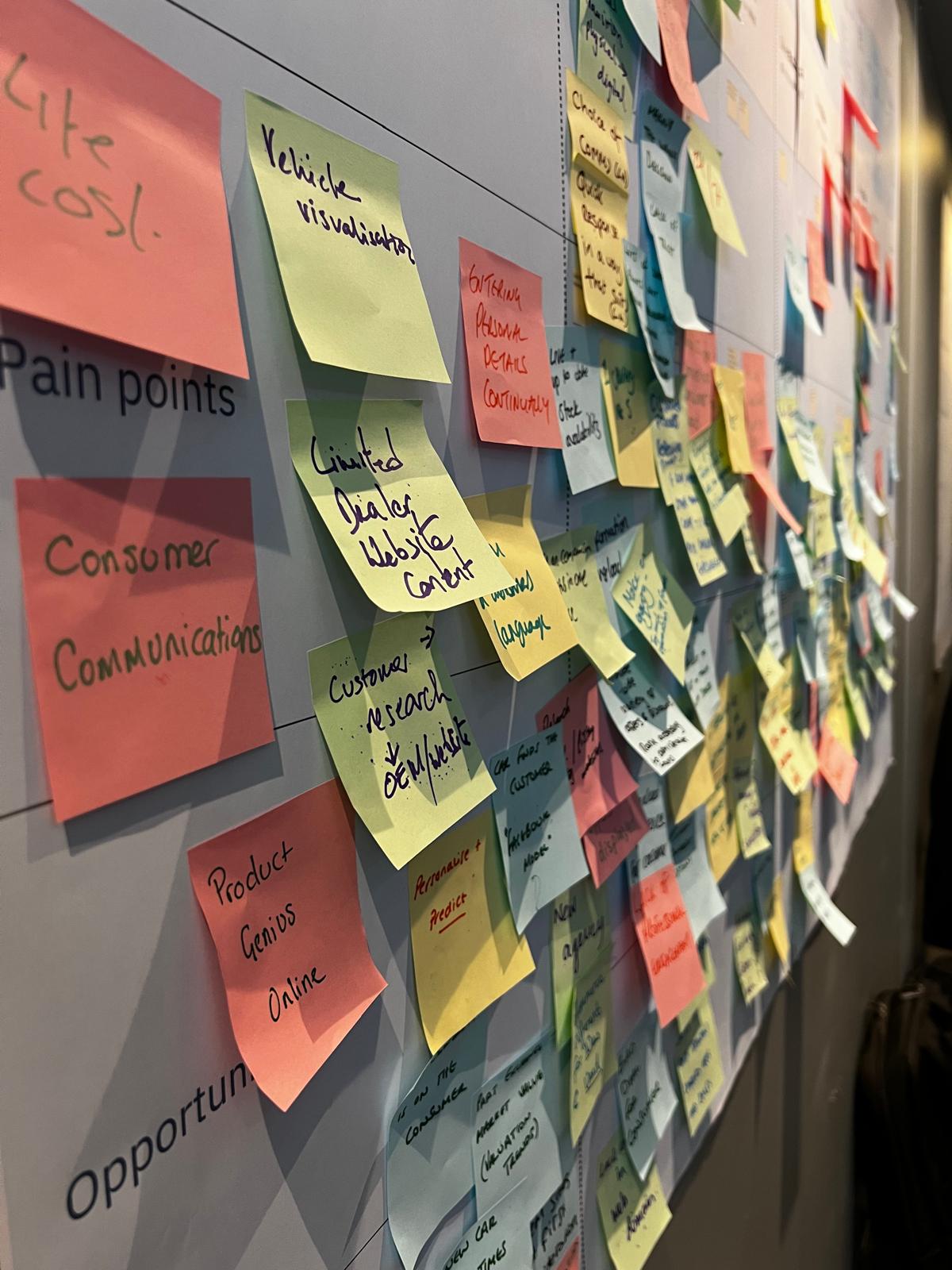

Learning of the chaos behind paper based systems

Key Findings

The research revealed that principal technicians were managing between 20 and 40 concurrent jobs across multiple bays and skill levels, relying heavily on paper job sheets and whiteboards. This created constant interruptions, duplicated effort, and little visibility into overall progress.

From these insights, it became clear that workshop management needed to evolve into a more connected, transparent, and adaptive system. The goal was to reduce manual coordination, empower technicians to make faster, data-driven decisions, and give every team member a shared view of what was happening across the floor.

I translated these findings into a set of clear requirements that would begin to guide solution development:

For Workshop Teams:

- Clear visibility into daily priorities and workload distribution

- Ability to flag blockers and request support seamlessly

For Customers

- Transparent service tracking from booking to completion

- Accurate time estimates and proactive status updates

For Principal Technicians:

- Reduce admin time from 2+ hours to under 30 minutes daily

- Provide real time oversight of all concurrent work

Research Outputs

Once the visits were completed, I synthesised findings into clear, shareable artefacts to help the team understand the pain points and opportunities identified through research.

A selection of research assets used to communicate key opportunities

Design Sprint

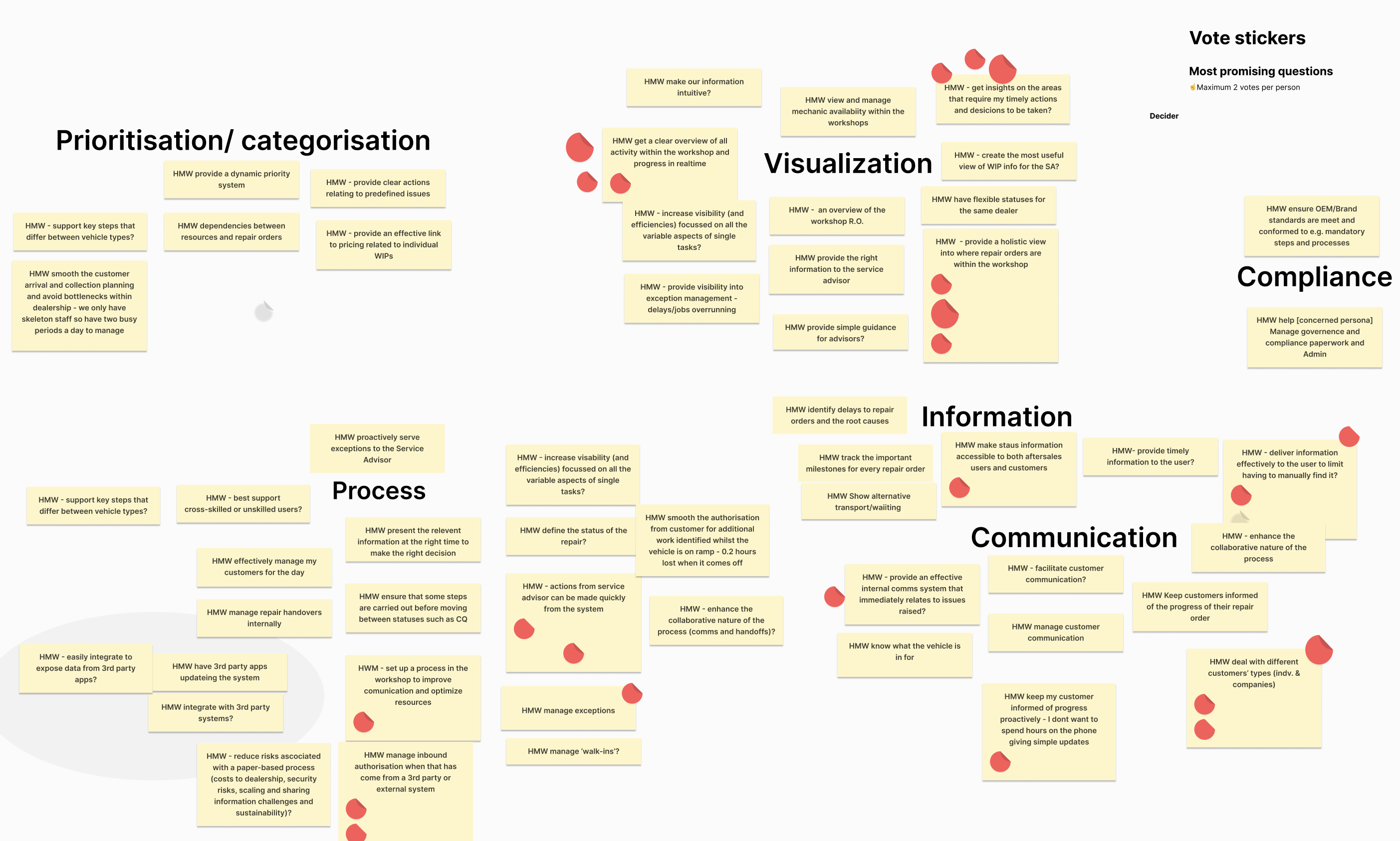

Building on the insights gathered during research, I led a design sprint to bring cross functional teams together and translate our findings into clear, actionable opportunities.

The workshop acted as an opportunity to dispel research findings, which went on to shape 2 days of hands activities to explore the problem space.

By the end of the sprint, we had a focused set of opportunities grounded in real evidence and user context. This built a strong foundation for ideation, and ensured alignment and buy in from key internal stakeholders.

Identifying pain points and creating ‘How Might We’ Statements

Ideation

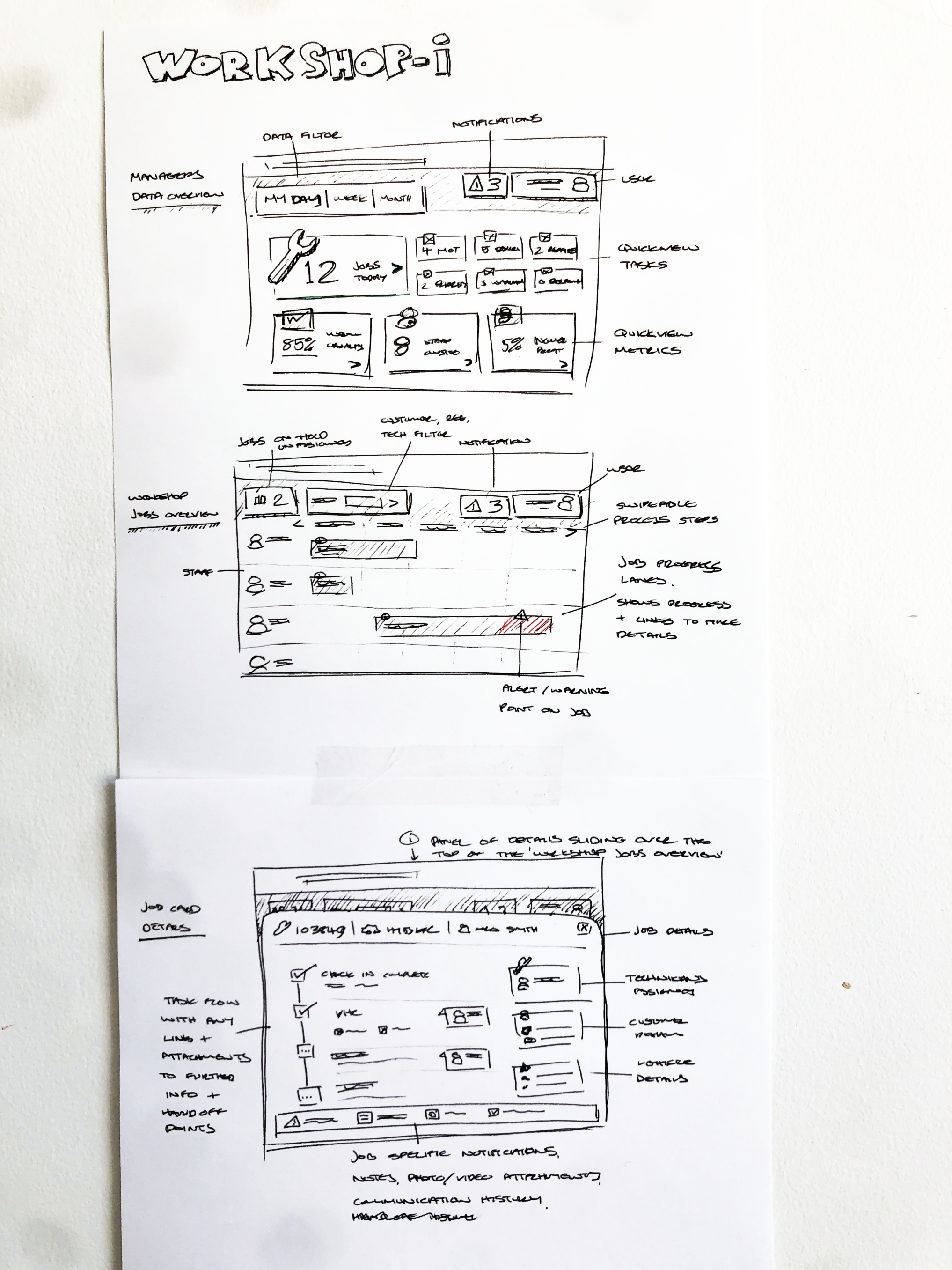

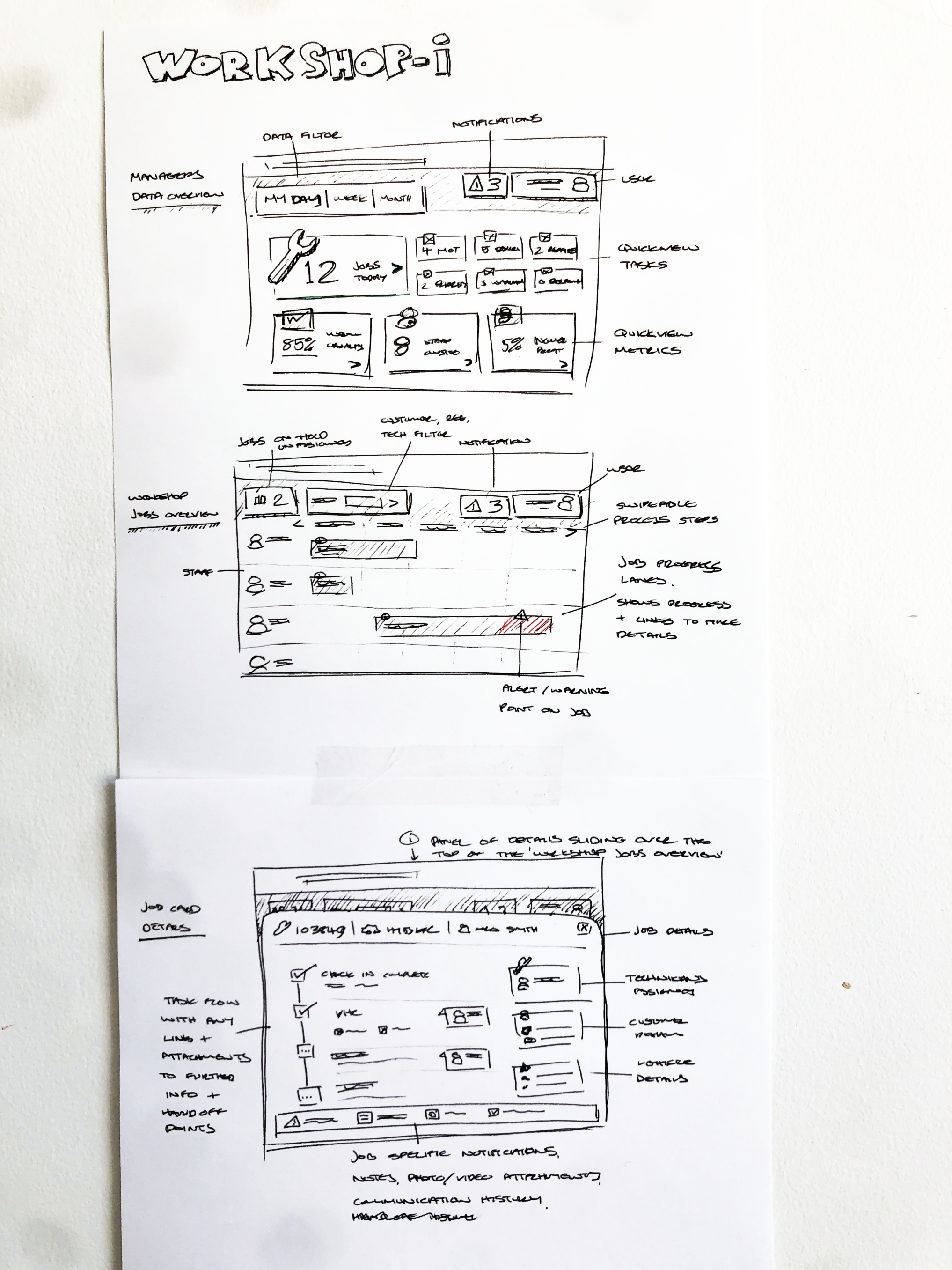

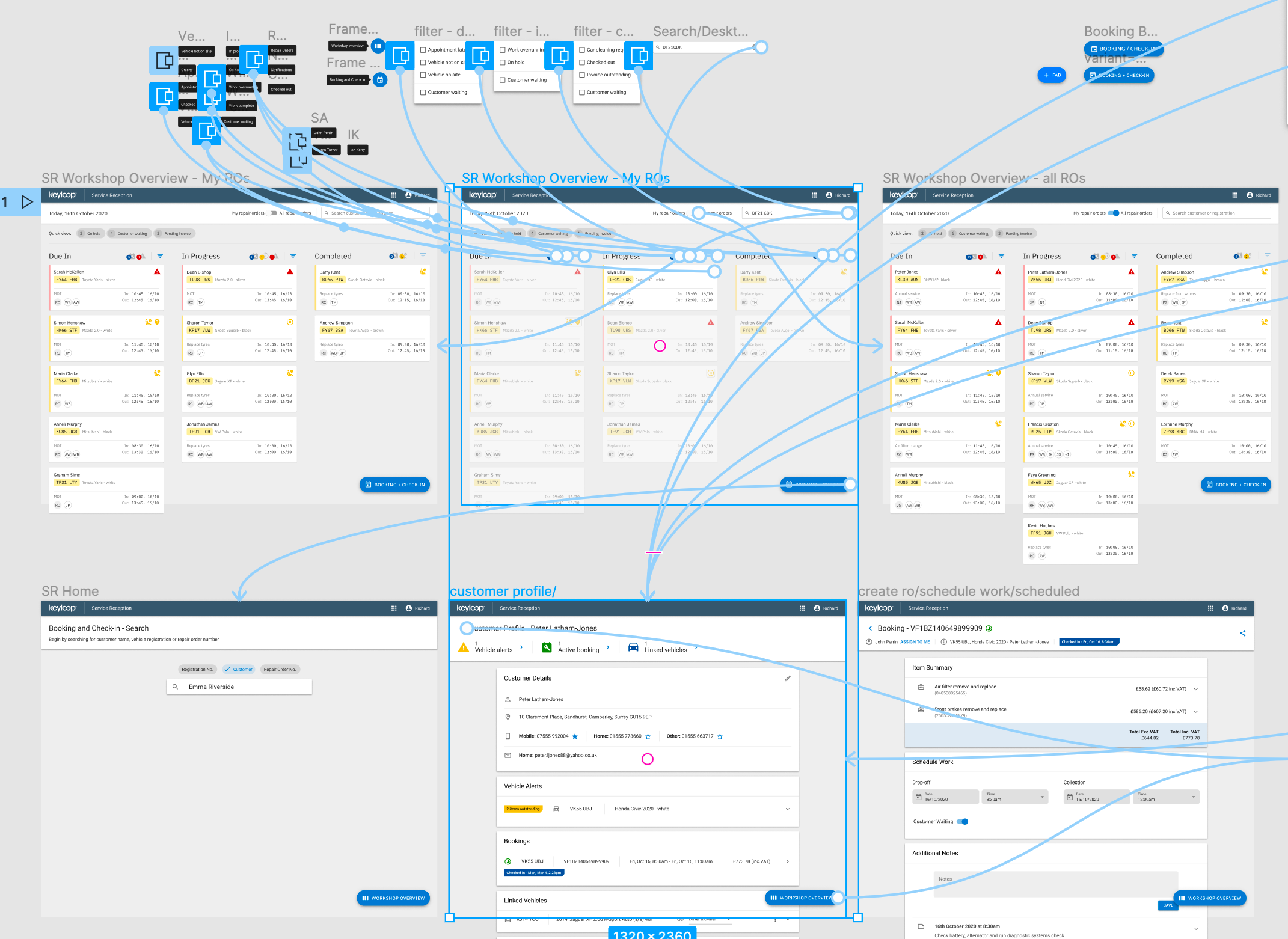

With a clear set of co-created opportunities defined, I moved quickly into rapid prototyping to test how different interaction models might bring the vision to life.

Early concepts explored how technicians could visualise and adjust their workload in real time. The goal was to create a system that didn’t dictate scheduling changes to teams, rather highlighted potential challenges, and offered pro-active solutions.

Initial Wireframe Sketches

First testable prototype

Testing

To validate the early prototypes, I ran a series of remote testing sessions with the same users who had contributed to initial discovery. This continuity gave us richer feedback, as participants could immediately recognise how their earlier frustrations had been addressed in the designs.

Prototype testing with users

Feedback was overwhelmingly positive. Users appreciated how visual the new system felt compared to their existing spreadsheets and whiteboards. They could instantly see who was available, which jobs were at risk, and where bottlenecks were starting to form.

“Being able to see every technician’s load like this... that’s exactly what we’ve been missing. We’ve got the data, but it’s never this clear.”

Lead Technician

“This is going to save me hours every week. I can focus on customers, not chasing paperwork from the workshop team.”

Service Advisor

“As a workshop team, we’re always reacting to changes that impact different jobs... a tool like this would help us to predict what’s going on, and start working more proactively”

Head of Aftersales

MVP Development

The feedback confirmed that we were addressing the core problems effectively, but also revealed new opportunities to improve the experience further. We incorporated these insights into additional design iterations, refining the solution with each round of testing.

Working closely with the Product Manager and engineering teams, I then helped define the MVP, prioritising features that delivered the greatest real world impact while keeping development effort manageable.

‘Noodling up’ the final MVP flows

Solution

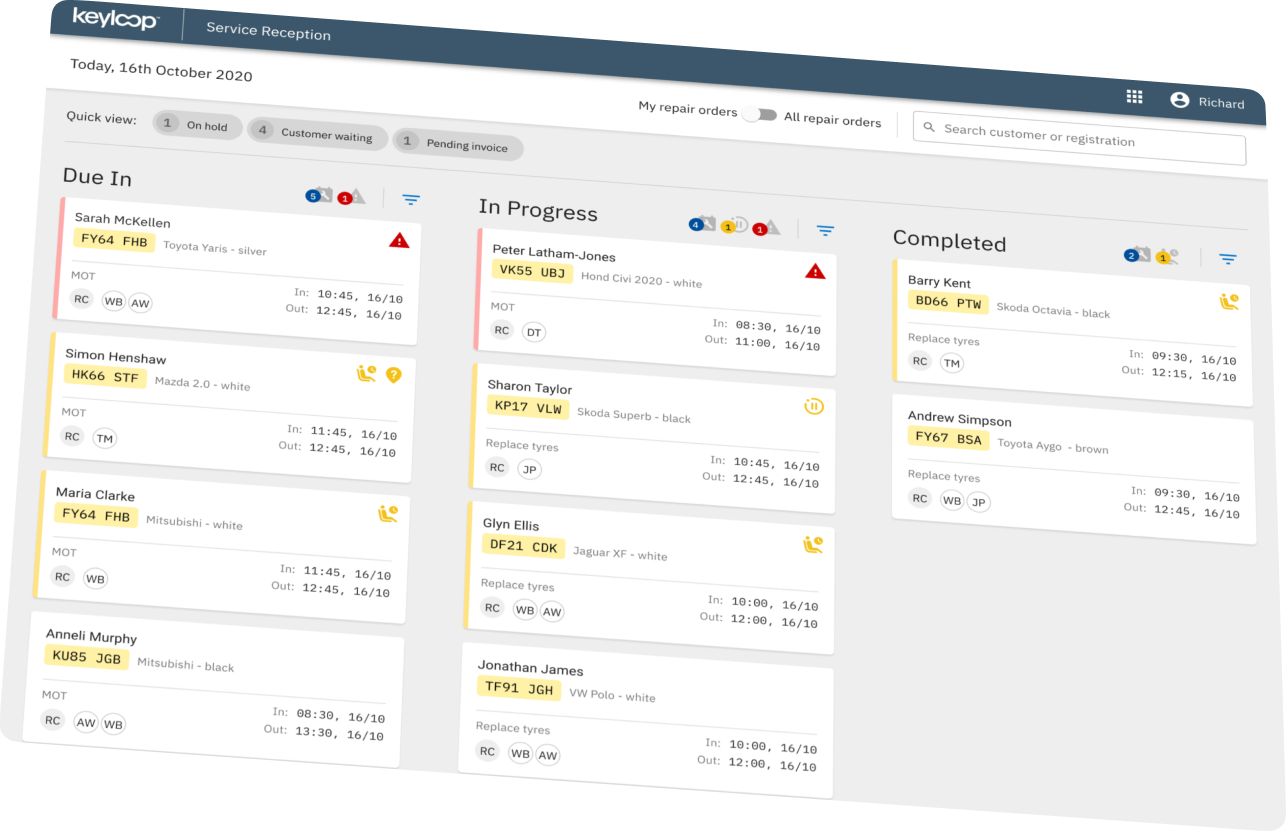

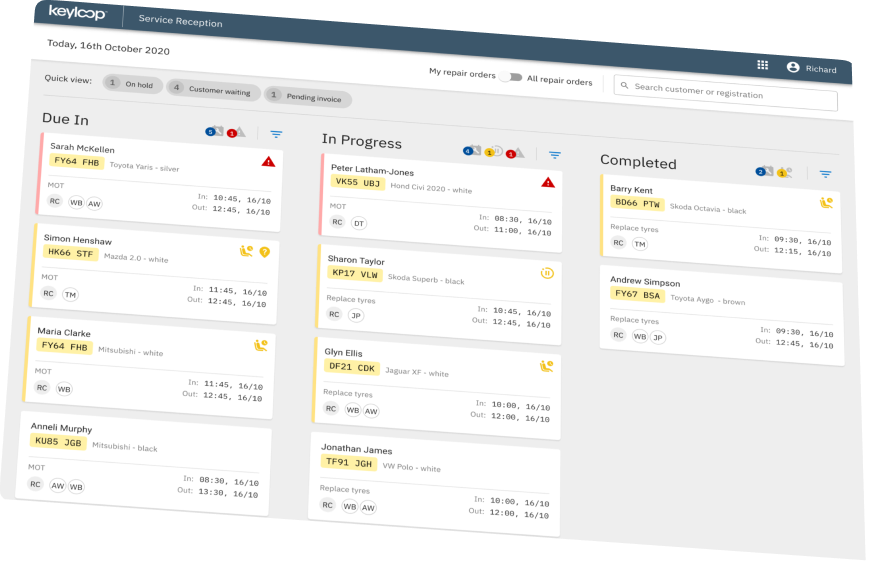

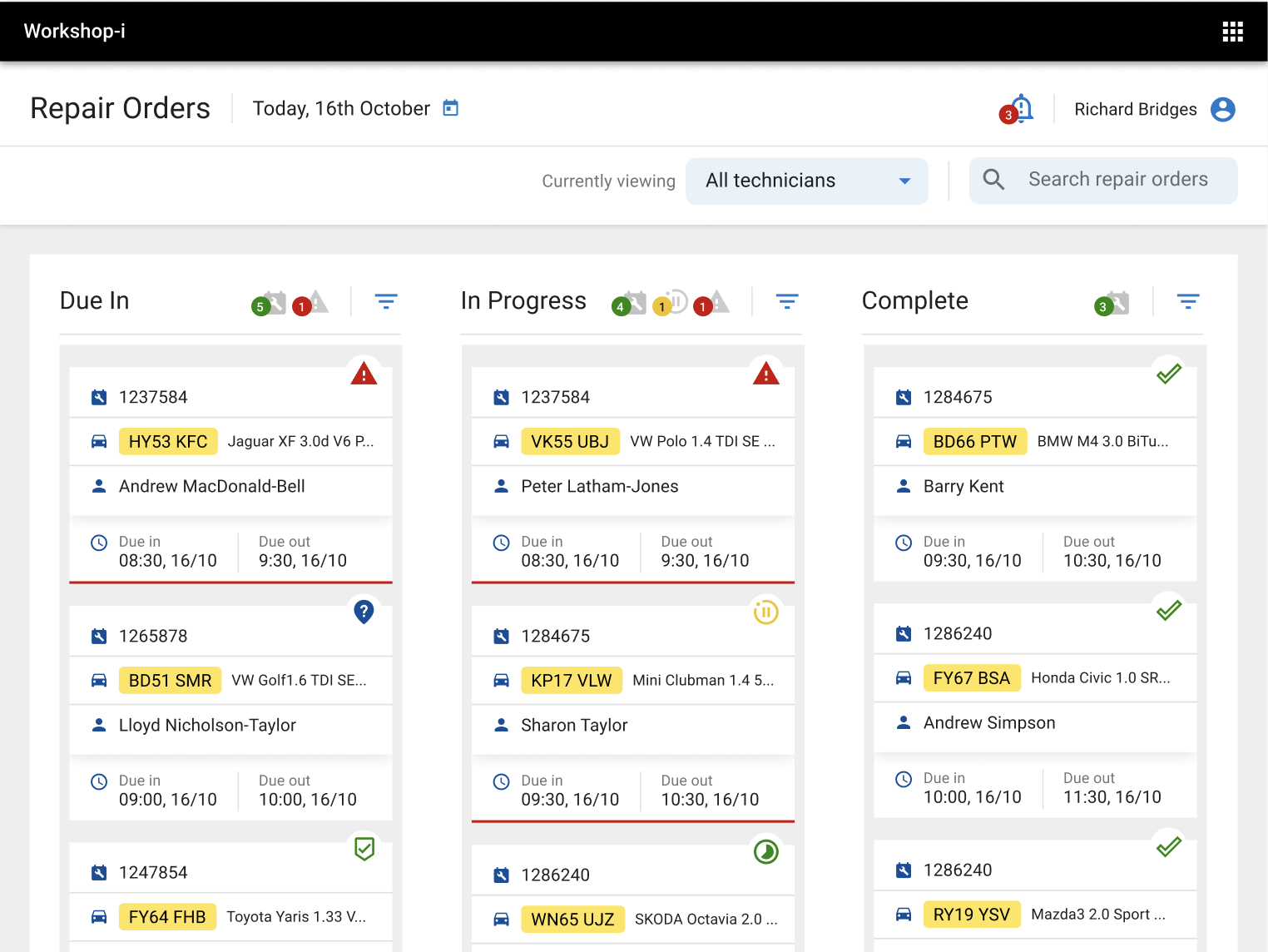

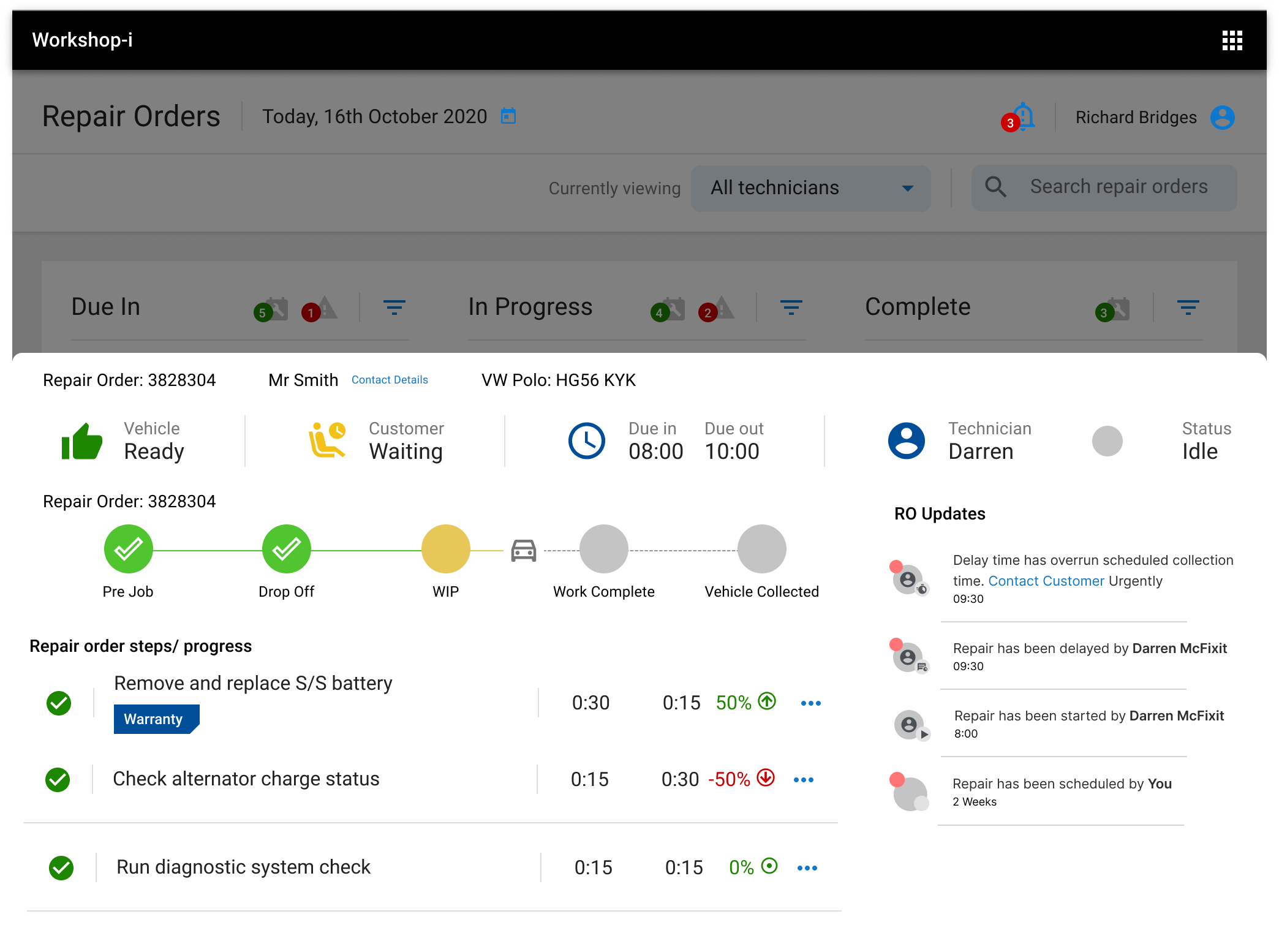

The new ServiceHub Scheduler delivered a single, connected view of workshop operations.

Key features

- Visual overview of daily and weekly workload

- Smart scheduling suggestions with manual overrides

- Real-time job progress tracking

- Integrated technician to manager to customer communication

- Seamless connection to other ServiceHub modules

Together, these features transformed chaotic paper processes into an intelligent, human-centred system that balanced speed with clarity.

Impact

20%

Increase in upsells

Timely flagging for extra work, alongside a notification feature enabled more customer approvals while the vehicle is still on the ramp.

5x

Faster customer queries resolved

Automated status updates mitigate the need for physical interdepartmental communication, enabling front of house teams to answer questions on the spot.

45 mins

Daily time save

Pilot sites measured a time saving of up to 45 minutes per technician daily - mainly from reducing time requirements for chasing paper based job cards.

“I used to spend half my morning trying to figure out what each technician was working on. With this view I can make decisions instantly.”

Lead Technician

Group 1 Automotive Service Center

Final solution in use at a pilot site